Chemtronics is the industry leader in solutions for the electronics, telecommunications, and critical environments markets.

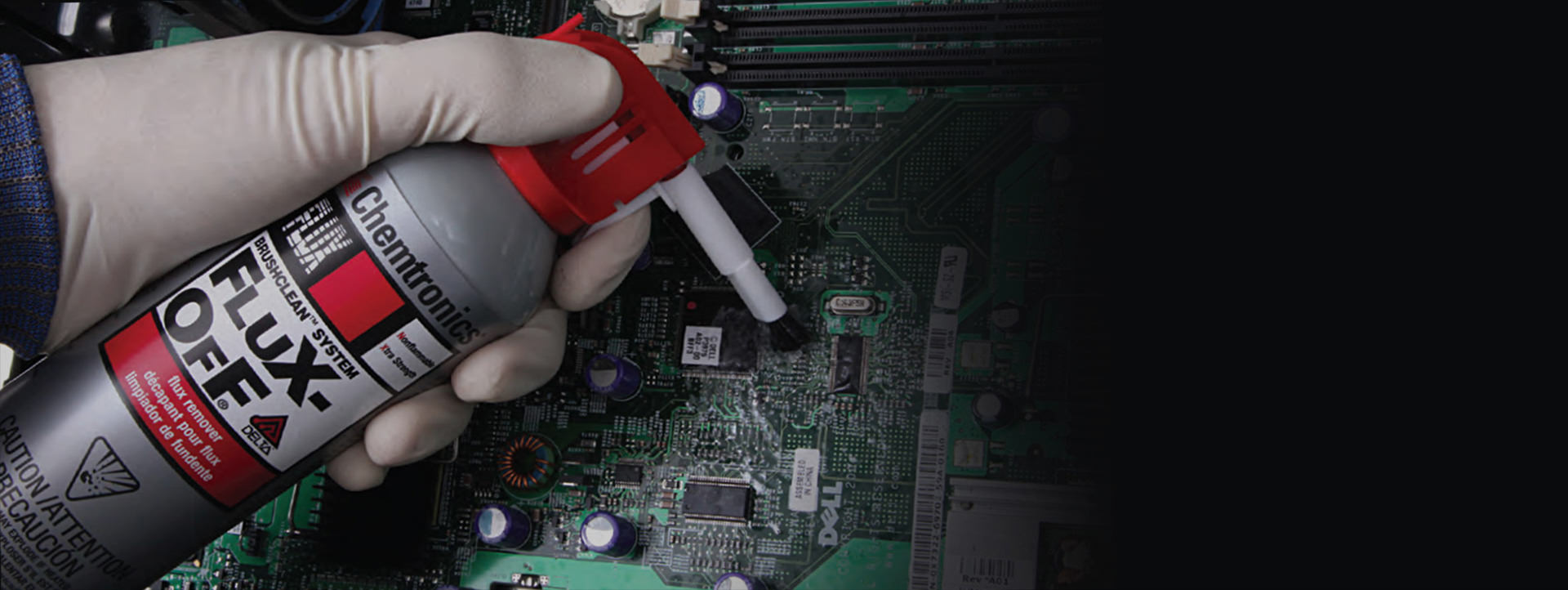

Our full line of products is engineered to meet all your cleaning, coating, and maintenance needs.

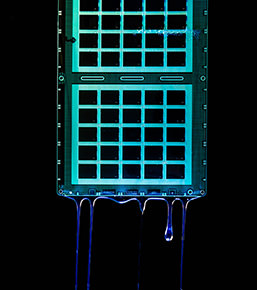

Conformal

Coating

Chemtronics Konform® Conformal Coatings are used for spray, dip tank, and brush applications. They protect printed circuit boards, components and flex circuitry from damage.

Take Me ToConformal Coating

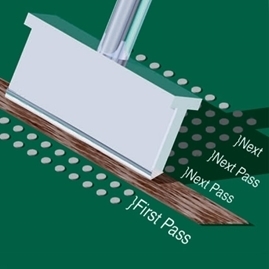

Contact

Cleaners

Remove environmental contaminants and protect contacts from corrosion and frictional wear. Restore electrical continuity to all electronic and electrical contacts.

Take Me ToContact Cleaning

Cleaner

Degreaser

The most effective products made for the critical cleaning and degreasing of electronics, electrical assemblies, and any other highly sensitive electronic components.

Take Me ToCleaner Degreaser

ESD-SAFE

SWABS

Coventry™ Sterile Sampling Swabs have been engineered to efficiently collect biological fluids for elution and analysis especially nasopharyngeal and oropharyngeal sampling.

I Want ToLearn More

Innovation

Starts With You

We analyze your challenges to create unique solutions and new technology. That's why we want to hear from you. Tell us your story, and we'll get started on your solution.

Get StartedChemtronics Tips & Product Blog

READ MORE

READ MORE

READ MORE

READ MORE